Source: nanowerk.com

(Nanowerk Spotlight) Research on electrochemical energy storage devices is driven by requirements for both energy density (how much energy can be packed in a cell) and power density (how fast the cell can deliver the energy).Standard capacitors that regulate flow or supply quick bursts of power can be discharged and recharged hundreds of thousands of times. Electric double-layer capacitors – generally known as super- or ultracapacitors – are hybrids that hold hundreds of times more energy than a standard capacitor, like a battery, while retaining their fast charge/discharge capabilities.

These supercapacitors are emerging as a key enabling storage technology for use in fuel-efficient transport as well as in renewable energy. Supercapacitors offer a low-cost alternative source of energy to replace rechargeable batteries for various applications, such as power tools, mobile electronics, and electric vehicles.

Researchers have come up with various electrode materials to improve the performance of supercapacitors, focussing mostly on porous carbon due to its high surface areas, tunable structures, good conductivities, and low cost. Emerging carbon nanomaterials, such as graphene (read more: "Graphene supercapacitor holds promise for portable electronics") and carbon nanotubes (read more: "Solid-state energy storage takes a leap forward with nanotube-based supercapacitor"), show great potential especially for high power applications. However, for large-scale commercial application, materials with similar structures and properties but much lower cost are highly desirable because even the most economically produced graphene-like material is nowhere near cost competitive with petroleum- or biowaste-derived carbons achieved via simple pyrolysis or hydrothermal methods.

Researchers in Canada have now reported ("Interconnected Carbon Nanosheets Derived from Hemp for Ultrafast Supercapacitors with High Energy") the successful hydrothermal-based synthesis of two-dimensional, yet interconnected, carbon nanosheets with superior electrochemical storage properties comparable to those of state-of-the-art graphene-based electrodes.

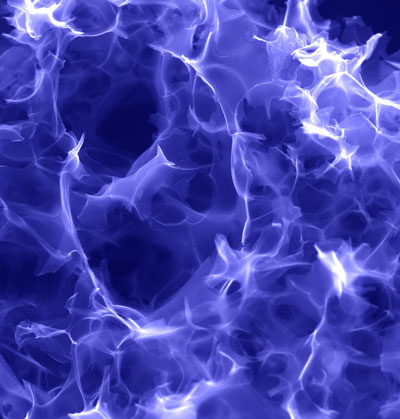

SEM micrograph highlighting the interconnected 2D structure of

hemp-derived carbon nanosheets. (Image: Mitlin group, University of Alberta)

"We were able to achieve this by employing a biomass precursor with a unique structure – hemp bast fiber," Zhi Li, a post doc researcher in David Mitlin's group at the University of Alberta, tells Nanowerk. "The resultant graphene-like nanosheets possess fundamentally different properties (pore size distribution, physical interconnectedness and electrical conductivity) as compared to conventional biomass-derived activated carbons."

In a previous Nanowerk Spotlight ("Converting eggshell membranes into a high-performance electrode material for supercapacitors") last year, we reported on the group's innovative use of biomaterials to fabricate supercapacitor electrode materials. With their eggshell membrane they achieved excellent electrochemical activity.

In their new work, driven by their search for simple process and cost-competitive precursors to prepare stacking-free graphene-like carbon materials, the team went one step beyond the eggshell work to work with the nanostructures naturally existing in hemp fibers.

"The abundantly available biomass in nature is mainly composed of cellulose, hemicellulose and lignin," explains Li. "These three compositions are organized in unique micro- and nanostructures, depending on the type of biomass. These structures could play a very important role if we can properly utilize the slight chemical activity difference between these three compositions."

Hemp bast fiber (bast fibre is collected from the inner bark – or 'bast' – surrounding the stem of the plant), for instance, has a multi-layered structure composed of cellulose, semi cellulose, and lignin. While the inner and outer layers are are mainly composed of semi cellulose and lignin, the middle layer is primarily crystalline cellulose. This middle layer represents more than 85% of the total wall thickness and is itself a layered structure consisting of microfibrils that are 10-30 nm in diameter. The microfibrils consist of bundles of highly crystalline cellulose elementary fibrils ( about 2 nm in diameter) surrounded by semi cellulose.

"We used a hydrothermal process to remove the inner and outer layers while at the same time loosen the connections between the microfibrils in the middle layer," explains Li. "In a subsequent activation process at 700-800°C, potassium hydroxide (KOH) melt penetrates into the loose connection between the microfibers, causing full separation of layers as sheets. Meanwhile, the layers are carbonized and activated by the KOH, further reducing their thickness and generating micro and mesoporosity."

The resulting carbon nanosheets (CNS) have a graphene-like, thin layer structure filled with large amount of pores. The layers are organized in a three-dimensional way, which makes it a very promising electrode materials for high-power (high-current) applications.

"When used for supercapacitor electrodes, this material exhibits great electrochemical performance comparable to state-of-art activated graphene materials – at a much lower cost," emphasizes Huanlei Wang, the first author of the paper. "Thanks to the unique layer structure of hemp fiber, which has been partially preserved in our work, the CNS material can work at much higher power density. For example, the maximum power density of CNS based supercapacitors is more than 3 times higher than commercial supercapacitors (49 vs 14 Kw/Kg). In addition, the supercapacitors we developed can work in a wide temperature range of 0-100°C, which makes them an ideal high-power energy storage solution working in harsh environments."

Given the vast number and varieties of nanostructures that exist in nature, taking advantage of these structures and materials for fabricating carbon nanomaterials could become a very promising strategy.

The team's next step, which they actually are already working on, is trying to achieve thinner carbon nanosheets by optimizing the synthesis procedures."We are very curious to find out what level of power density the materials can delivery if we can make them less than 5nm thick," says Wang.

Hemp's many uses makes it a way out of the recession for the US - that is why the politicians are listening - there is now an amendment to the Farming Bill introduced by Patrick Leahy. Much activism by long term hempsters is paying off. Please join this activism and sign the petition at www.minawear.com/about-us/ - that is work by Mina Hegaard and her brother who blogs at www.hempforvictory.blogspot.com

ReplyDelete